GET A FREE INSTALLATION TOOL ON ORDERS OVER £300 TODAY!

Supplying high quality, affordable ground screws for garden rooms, outdoor buildings and decking UK wide

Ground screws are reusable and have little impact on their surrounding environment.

Ground screws offer structural integrity at a cost much lower than concrete base foundations.

Our ground screws can be installed by hand in a matter of minutes.

Stop digging and start screwing! It’s half the work with zero mess.

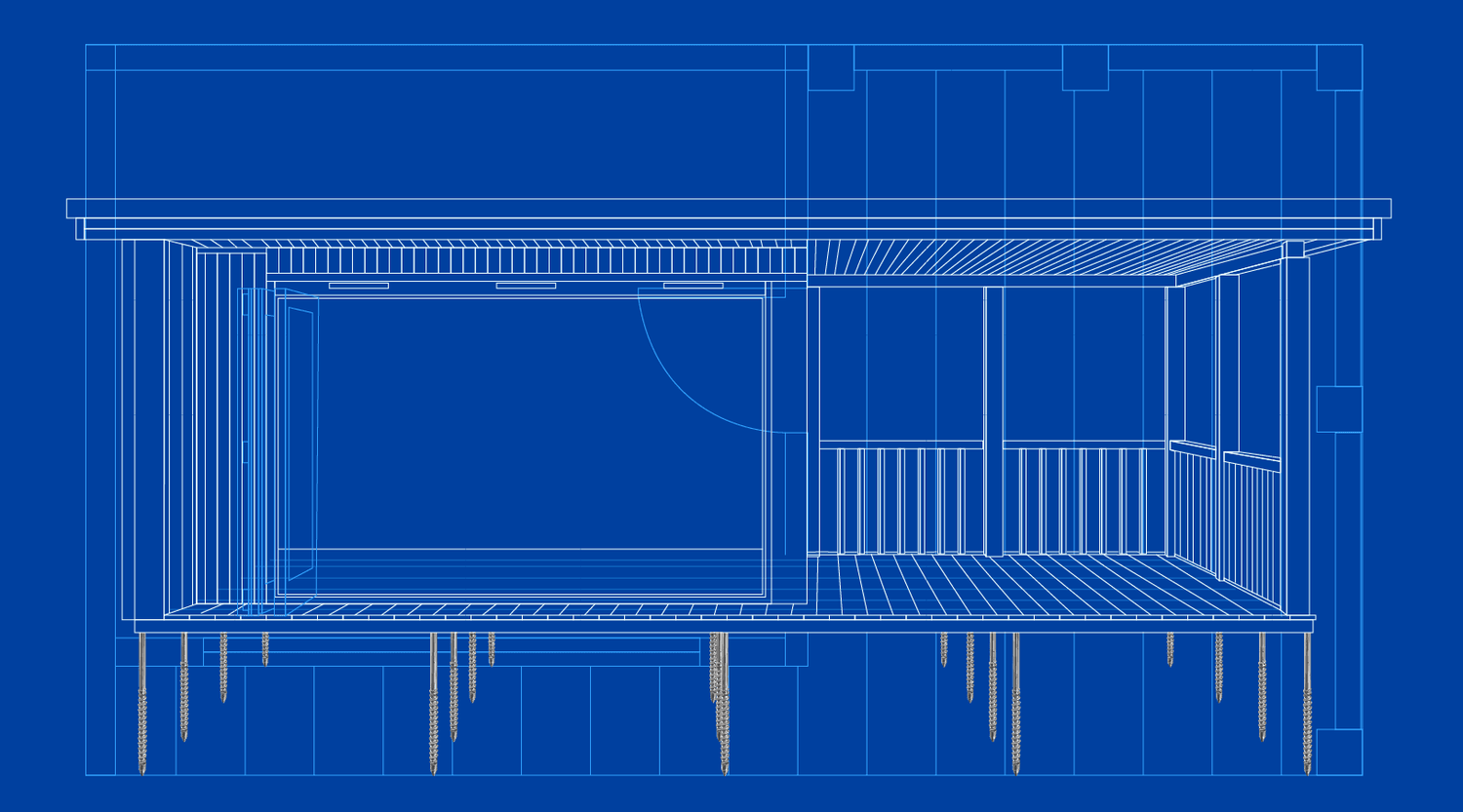

Ground screws, also known as screw piles or ground anchors, are a type of foundation system used for supporting various structures. Galvanised to provide long-lasting protection against corrosion, ground screws are driven into the ground to provide stability and support. Ground screws have helical threads that allow them to be screwed into the soil much like a wood screw into timber. Skin friction is created between the helical thread and the soil, allowing for large vertical loads to be applied to the ground screw and the weight transferred to the soil.

Ground screws can be used in a variety of soil conditions, including clay-based and sandy soils. Their load-bearing capacity can be adjusted by altering the size and length of the screw, as well as the number of helical plates attached to the shaft. This flexibility makes them suitable for a wide range of applications, from small-scale residential projects like decking and sheds to large-scale structures, including Annexes, timber houses and shipping containers.

One of the primary advantages of our ground screws is their ease of installation. They can be installed quickly using a range of tools, from simple handheld installation tools to electric ground screw installation machines. Construction time and labour costs tend to be much lower using ground screws compared to traditional methods using concrete.

The maximum distance between ground screws is 1.5m when using a timber frame base. The timbers used in the frame should be no less than 4”x2”. Standard shed floor bearers are typically 40mmx40mm and cannot sit directly on top of ground screws. A timber frame must be built to sit the shed bearers on top. Extending the distance between ground screws beyond 1.5m will allow the timbers to flex, or, start encroaching on the load-bearing capacity limit of the foundations.

The maximum distance between ground screws when using a SIPs (structural insulated panel) base is typically 1.2m, which is the standard width of a floor SIP. When using SIPs the joining timbers must sit on the ground screws, which will be every 1.2m with standard panels. If in doubt please send the SIP manufacturers drawings to info@sipsgroundscrews.co.uk and we can confirm the total number of ground screws required.

The minimum distance between ground screws is 5x the diameter, including the helix. For our 68mm ground screws the minimum distance between them is 440mm. For our 76mm ground screws the minimum distance between them is 480mm. Reducing the distance between ground screws beyond these values can lead to interference of load transfer and reduced load-bearing capacity of the foundations.

Our ground screws are hot dip galvanised with an average zinc plating thickness of 80uM. Hot dip galvanising protects ground screws through a metallurgical reaction where iron in the steel reacts with molten zinc to form a tightly bonded alloy layer. This layer, composed of zinc-iron alloys, creates a robust barrier against corrosion by acting as a sacrificial anode. The zinc corrodes preferentially, shielding the underlying steel from rust and environmental damage. Additionally, the coating's thickness and uniformity ensure consistent protection, enhancing the ground screws' durability and lifespan, making them ideal for long-term applications. Standard zinc coating depletion rates in the UK are around 1-2uM per year. The depletion rate varies with factors including moisture, humidity, soil pH and temperature.

Our ground screws offer a versatile, eco-friendly solution for various construction projects. Unlike traditional concrete foundations, our ground screws are easy to install, cause minimal disruption to the environment, and provide a robust foundation for structures of all sizes.

Benefits of SIPs Ground Screws:

We hold stock of over 10,000 ground screws of varying lengths to accommodate different structures and terrains. As a rule of thumb, no more than ⅓ of the length of the ground screw should be above ground. Extending the ground screws too far above ground can compromise the lateral stability of the foundations.

The following recommendations assume flat solid ground. The installer is responsible for ensuring the correct provision and installation of ground screws. Please contact our team at info@sipsgroundscrews.co.uk if you require advice:

The construction industry continues to have a large and lasting impact on the environment. At SIPs Ground Screws, we are motivated to help build a greener Britain. Our DIY ground screws are an eco-friendly alternative to concrete bases. SIPs Ground Screws offer high quality and affordable ground screws designed for easy self-installation.

Developed by a team of engineers with more than 10 years of experience, SIPs Ground Screws products are designed to provide strength and longevity in service.

Our ground screws are hot dip galvanised and receive rigorous quality control checks after production and before dispatch.

Ground screws are the ideal foundation system for garden rooms, offices and outdoor buildings.

Choose from our range of ground screws, brackets and installation tools to build the foundations for your garden room.